Mewe production digital factory EcoMESA (manufacturing enterprise production process execution management system) system is a set of production information management system for manufacturing enterprise workshop execution layer.

It provides a system-wide management module based on MES (Manufacturing Executive System: manufacturing executive layer), including manufacturing data management, planning and scheduling management, production scheduling management, quality management, equipment management, project kanban management, production process control, bottom data integration analysis, upper data integration decomposition and other management modules, and ERP system docking to obtain Production orders, support visual production scheduling; support work reporting management, complete personnel status and equipment status correlation, and quality status correlation. Provide production management, equipment management, production output monitoring and work reporting, work order progress board, process parameter management, quality management and other management modules. It realizes real-time and automated analysis and evaluation of OEE data, helping users to improve operation management and production operation efficiency.

Adopt ECT DAQ (Data Acquisition) - a highly available data acquisition and distribution platform based on OPC UA protocol

EcoMESA is a digitally advanced, open, reliable and comprehensive manufacturing collaborative management platform integrating welding, painting and final assembly processes.

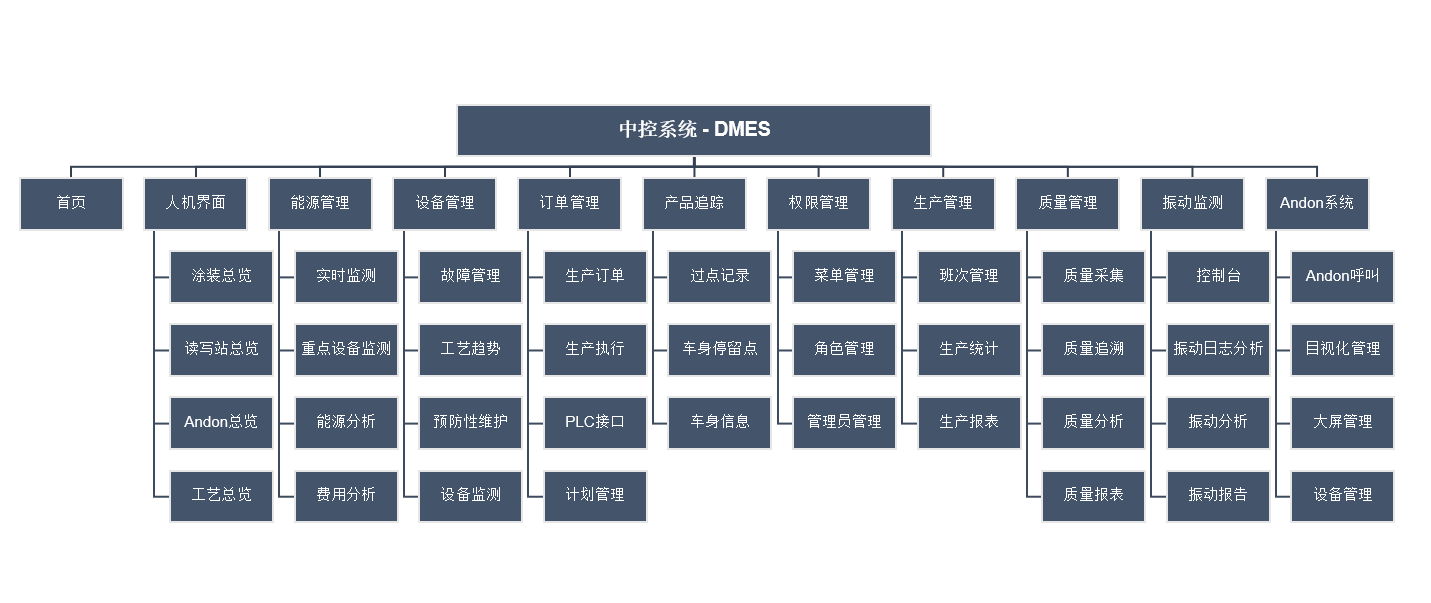

功能模块图

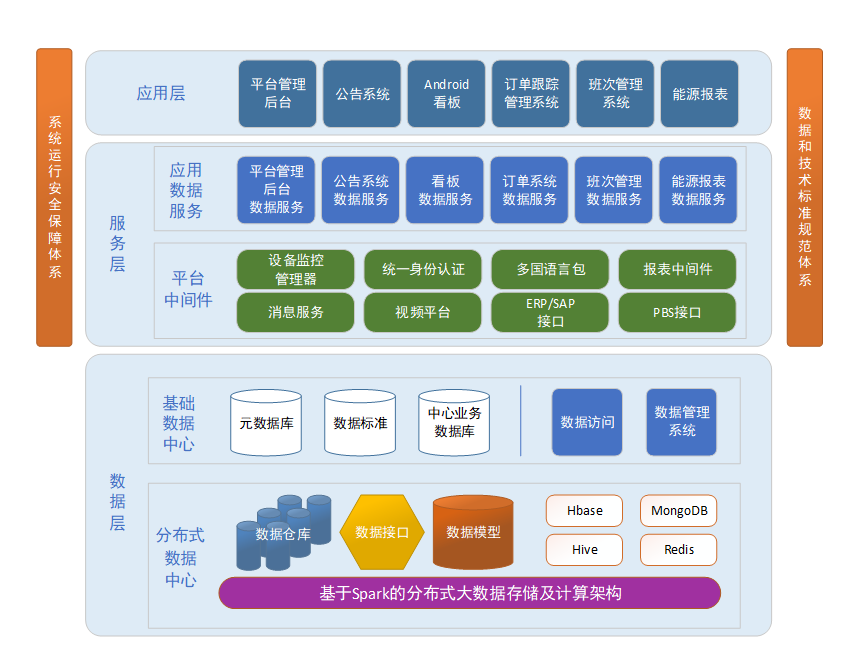

系统架构图

- Energy Saving Strategy

- Statistical Analysis

- Energy consumption threshold warning

- Real-time decision analysis of production data

- Millisecond data acquisition

- Compatible with PLCs of mainstream manufacturers and supports multiple device communication protocols

- Support top ERP and MES platform provider integration

- Support terabyte level data storage

- Support cluster deployment

- Real-time data backup

- Abnormal alarms

- EcoMESA reasonable process, BOM and production planning, and collaborate with raw material inventory management to develop an accurate bill of materials to help customers achieve on-time production.

-EcoMESA comprehensive data collection and statistical mechanism, from equipment, personnel, process and other dimensions of statistics related to the production process, to help customers understand the production situation, reasonable deployment of resources.

- EcoMESA can provide accurate statistics including output, time spent and raw materials for different granularity of personnel, shift, work station and production line, effectively reducing the accounting work of work hours and performance.

- EcoMESA helps customers to achieve product quality traceability through monitoring and recording of production process materials, personnel, equipment, processes, environment, etc.