If you need an industrial solution, we can provide it for you.

WinMOD Virtual Simulation

WinMOD Virtual Simulation

Virtual simulation is a way to protect software quality, minimize risks during commissioning, visualize the production line during the design phase to ensure proper production operation, optimize the process before commissioning, and save costs by reducing actual commissioning time.

Automotive Automation

Automotive Automation

Mewei Technology mainly serves the automation projects of most of the domestic auto factories such as Volkswagen, BMW, Mercedes-Benz and Chery. The company has hardware, software and production specifications in line with automotive industry standards, and a group of outstanding design engineers in the automotive automation industry, and is committed to continuously providing customers with the latest automation technology.

Industrial Information System

Industrial Information System

Unlike traditional information systems, ECT-DMES introduces the concept of business intelligence into our system, which not only monitors the entire execution process of a factory from order taking to order completion, but also helps companies to analyze data on the manufacturing process to assist in decision making!

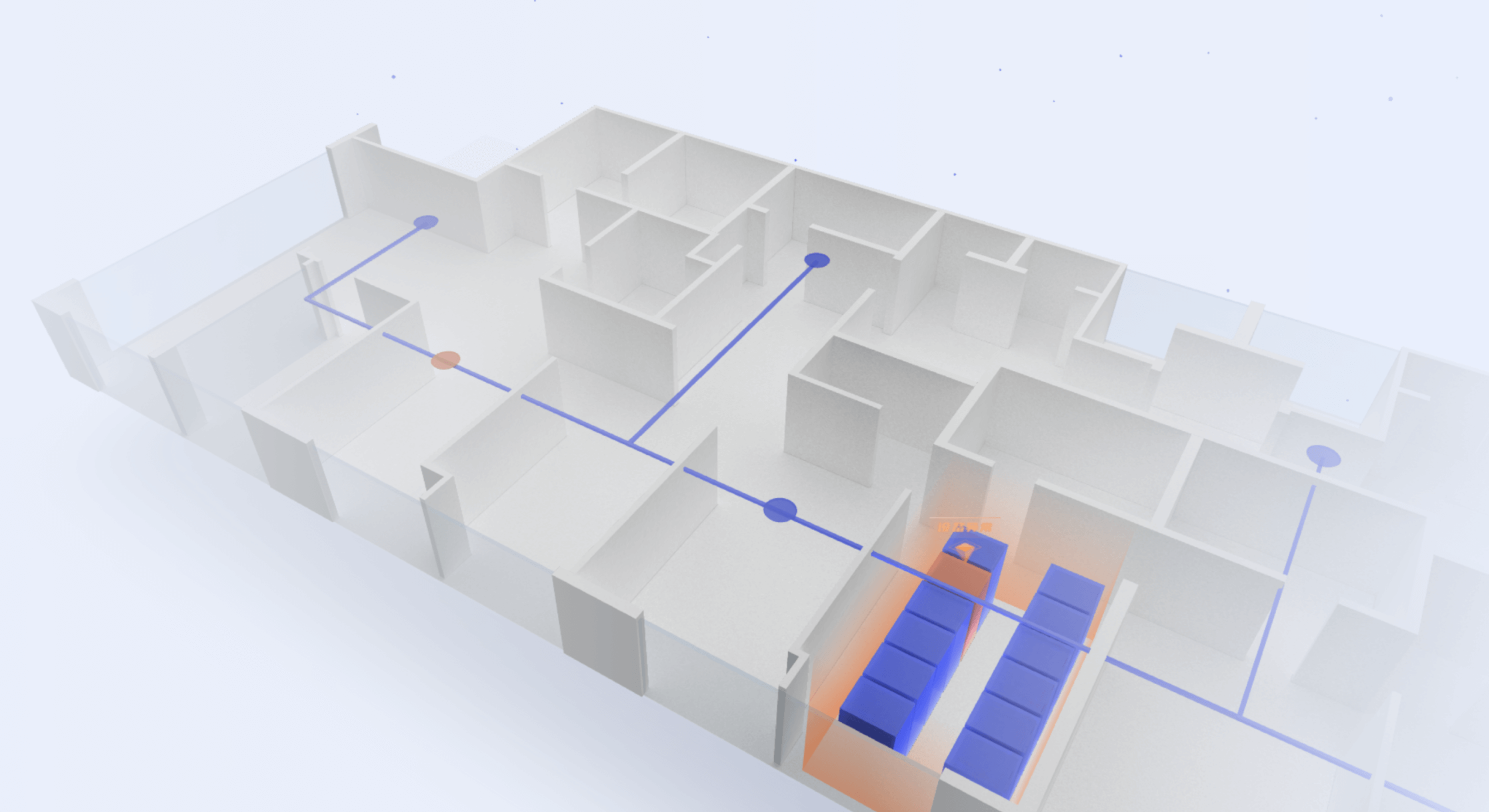

Industrial 3D Digital Twin System

Industrial 3D Digital Twin System

The 3D digital workshop control system based on digital twin technology aims to seamlessly integrate and upgrade the existing automation and informatization conditions of the workshop based on the physical factory, using technologies such as 3D simulation, Internet of Things, digital mapping, artificial intelligence and big data to realize monitoring of the overall workshop in the digital twin simulation world, realizing real-time data linkage, data drive, data query, abnormal alarm and other functions, and finally achieving intelligent, digital and visual management.