Modern manufacturing involves a wide array of production equipment, strict safety operation requirements for workshop workers, and limited workspace. Achieving pre-commissioning during the engineering phase, safety management, equipment maintenance during production, improving efficiency, reducing maintenance downtime, and implementing intelligent employee management are key challenges in the industry. There is an urgent need for a user-friendly and easily deployable debugging and maintenance system.

The iPOP product series is based on UWB (Ultra-Wideband) positioning technology. By receiving signals from base stations and calculating spatial coordinates using TWR (Two-Way Ranging) and TDOA (Time Difference of Arrival) algorithms, the system uploads real-time location data to a host computer. The host computer utilizes Unity for virtual reality visualization and communicates with PLCs in real time via Profinet wireless technology, enabling localized operations. This significantly enhances operational convenience and safety.

- Target Positioning, Tracking & Real-time Data Upload

- Real-time System Computation

- 3D Scene Reconstruction

- Multiple API Data Interfaces

- Built-in IMU & BMP for Precise Floor/Switching & Stable Positioning During Operator Movement

- Low Power Consumption & Long Battery Life

- Strong Anti-interference Capability

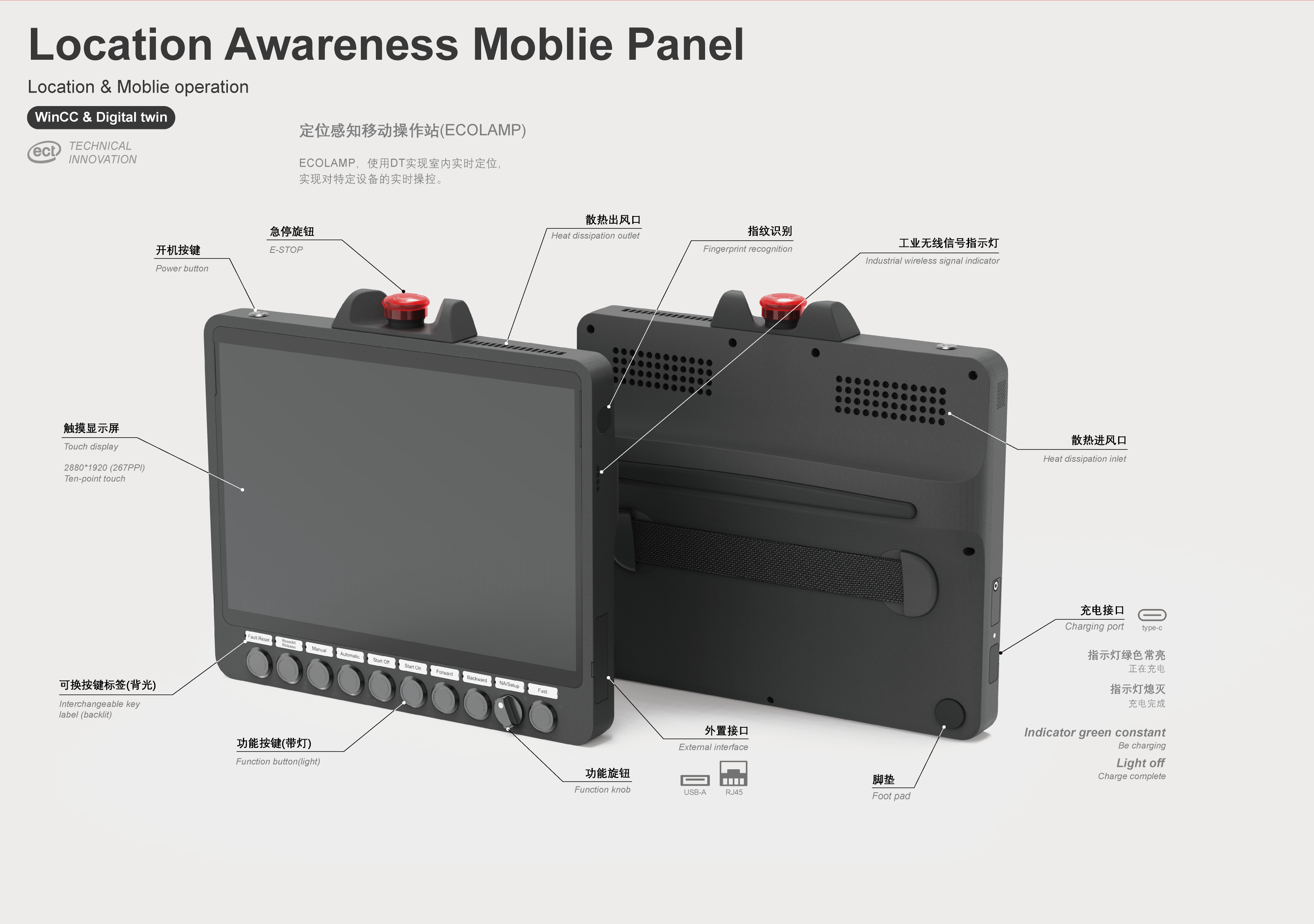

- mobile control panel product is powered by Type-C with a charging power of 65W

- power consumption is <20W

- product weight is 1650g

- product dimensions are 300.1x274.1x72.16mm

- mobile positioning accuracy is field-calibrated to <50cm

- battery life is >3h