The 3D digital control system based on digital twin technology integrates and manages all the information units provided by different manufacturers in the factory, collects data and information units of different frames in 3D digital factory in real time, and brings them together into a unified display mode of big data access, management and associated display analysis, realizing "one three-dimensional page with multiple information systems" control, allowing maintenance personnel to realize "one person with multiple machine management", breaking through information silos, and significantly improving work efficiency.

Support 24-hour automatic inspection and set schedule time automatic inspection; equipment use status 24H visual, real-time warning; support manual roaming and automatic roaming function.

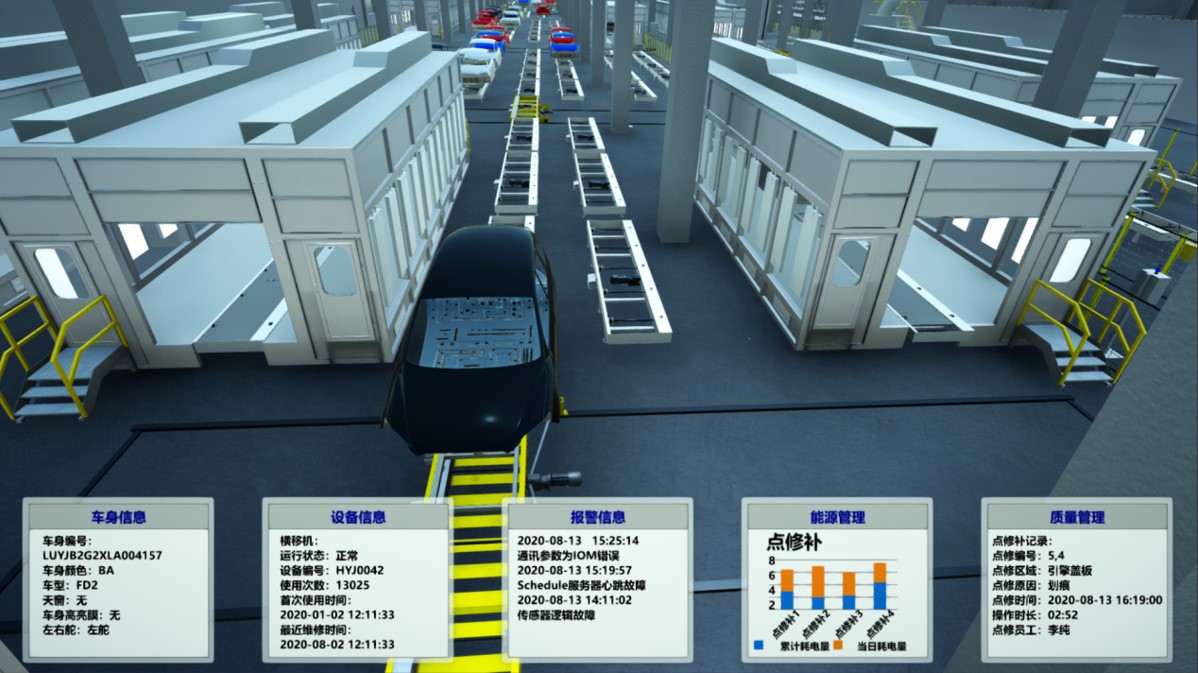

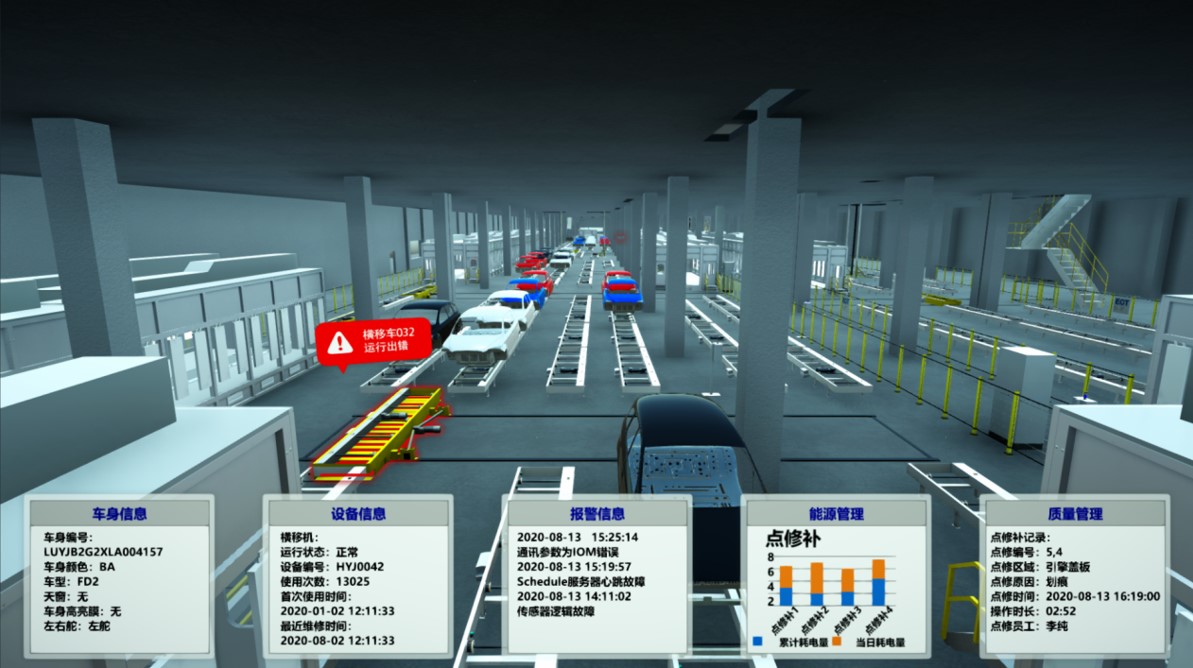

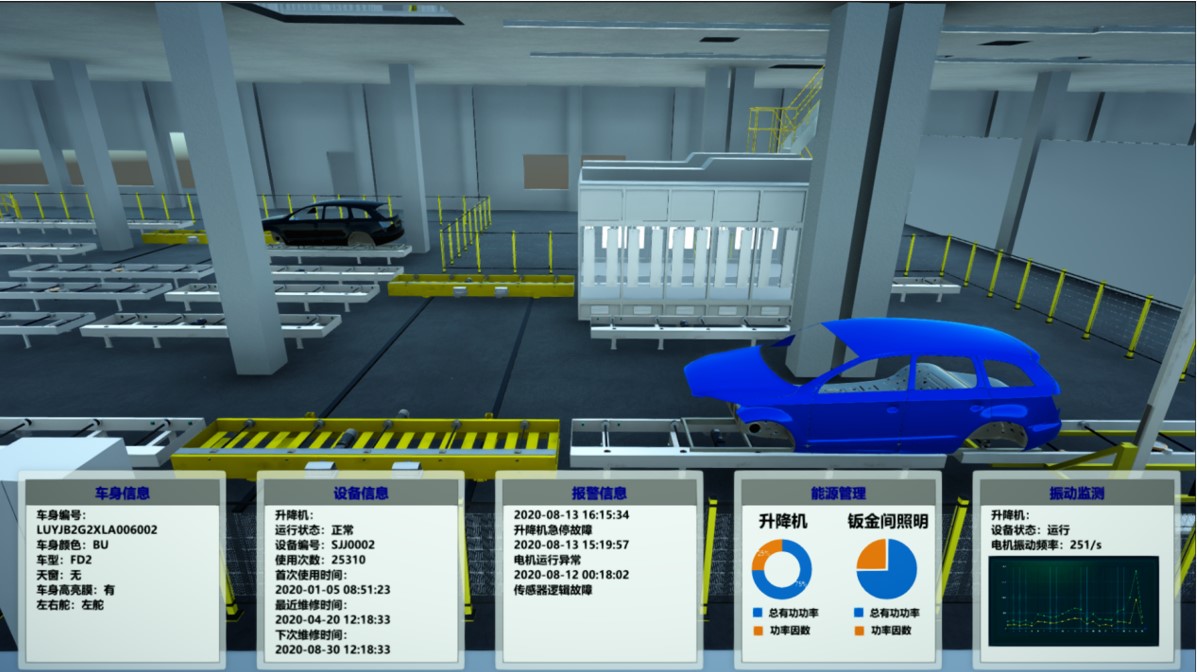

In the digital scene (three-dimensional visual environment) real-time collection and monitoring of key process data, data pre-processing, and text, graphics and other ways to process accidents, line crossing conditions, changes in working conditions and normal shift in a three-dimensional visualization of the health status of the equipment, the fault point, the causes of generation and treatment methods combined with the location of the digital simulation model for the performance, so that the fault more transparent, more accurate positioning.

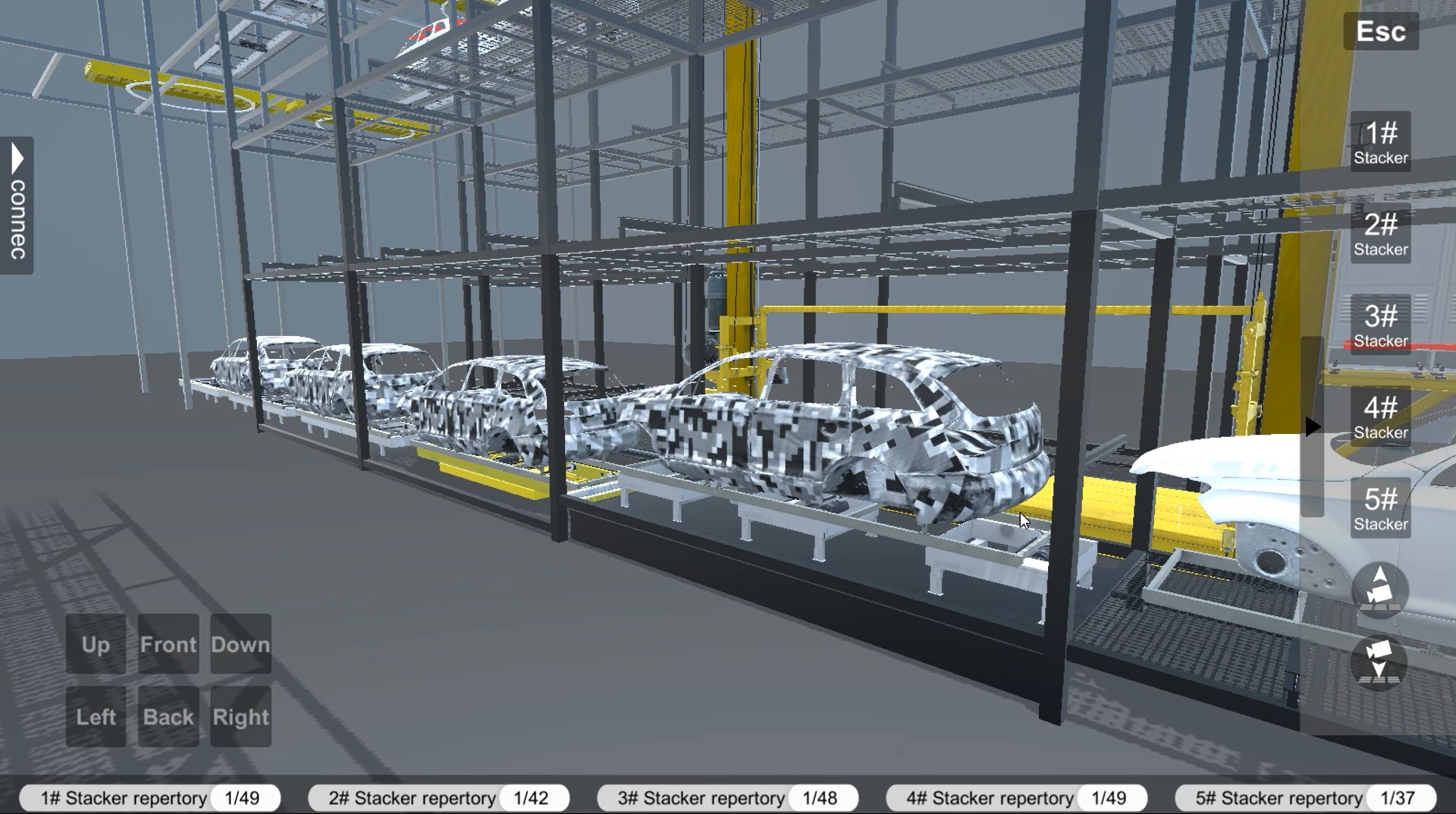

Realize the integrated and correlated digital asset library management of intelligent site information (3D model, engineering drawings and documents, etc.) with equipment 3D model as the carrier, and linkage of 3D graphics with equipment data and production data to make assets more transparent and digital. The linkage of 2D drawings with 3D models allows calling access to 2D drawings and other equipment documentation information in the 3D scene. In the 3D virtual simulation environment, through human-machine interactive operation, users can view the structure, component composition and technical parameters of the equipment in detail, understand and master the complete information of the equipment structure in an all-round way, and can conduct equipment fault diagnosis and treatment guidance.

The existing surveillance video data of the factory/workshop is connected to the 3D digital twin factory system based on digital twin technology, and users can directly click on the corresponding video surveillance tab within the platform to view that surveillance video, allowing real-time surveillance video to seamlessly integrate with three scenes to achieve global and full-area surveillance management.

● Digital twin of Chery Anqing paint shop

● Digital twin of the assembly line at BMW's Tiexi plant

● FAW BDC Risers

● Ulsan Honggi Rikku

Data Network:Click to visit

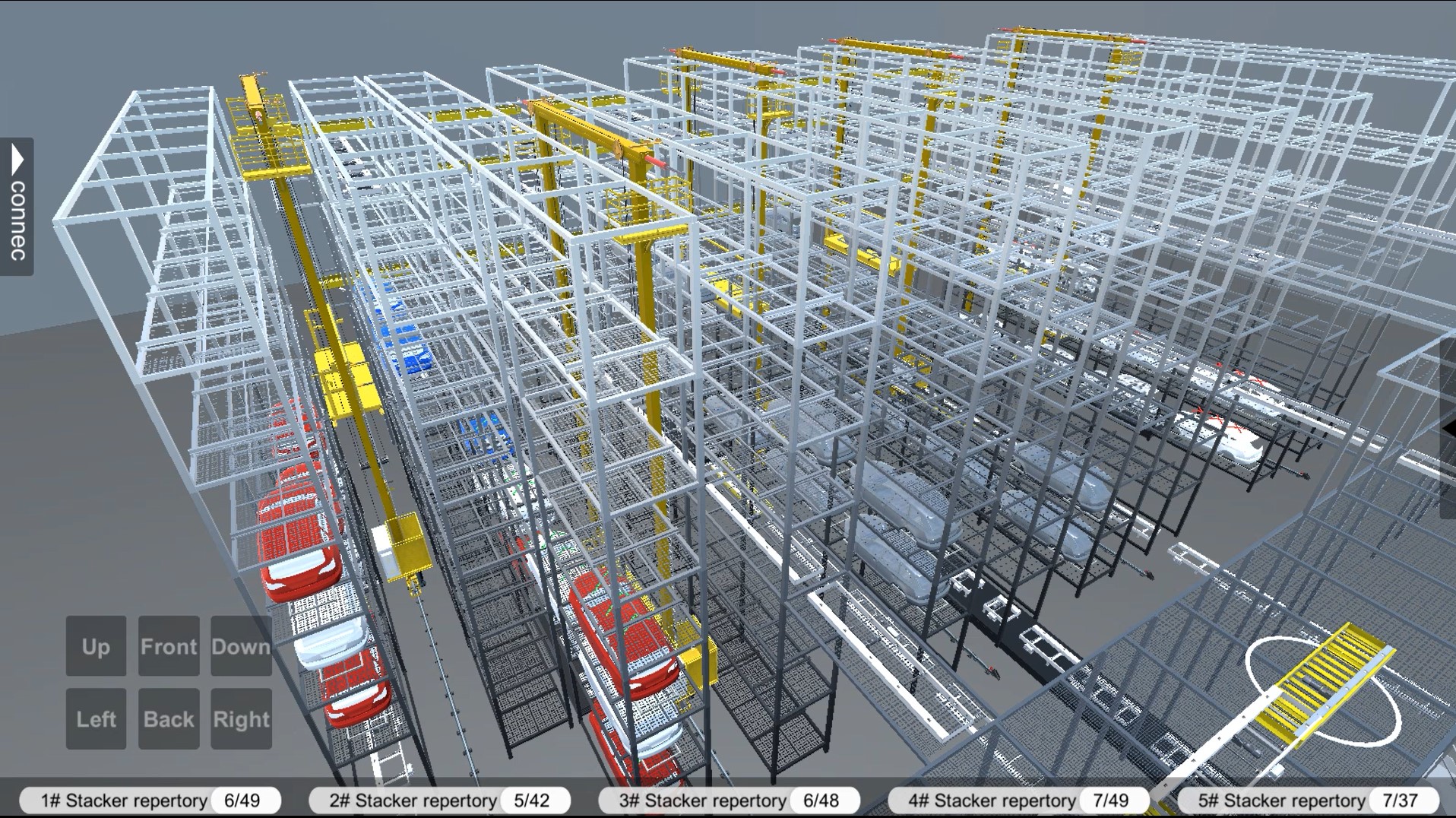

Using 3D simulation, Internet of Things, digital mapping, artificial intelligence and big data technologies to realize monitoring of the overall workshop in the digital twin simulation world, realizing real-time data linkage, data drive, data query, and abnormal alarm

- Integrated control of multiple information source systems

- Digital inspection

- Operation monitoring and fault diagnosis linkage

- Digital asset management

- Video fusion management