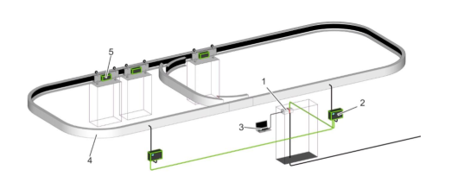

Weichai Power EBF logistics warehousing system

LJU IDM system

This project is an EMS conveyor line in the logistics industry. The controller is the latest IDM system multi-axis controller of LJU. PLC for Siemens 319F, the field bus for Profinet bus form. On-site equipped with two Siemens mobile screen KTP900F can control the field equipment and display alarms, information, running status and system messages. Compared with the conveyance line of automobile final assembly we made before, its conveyance speed is faster (the maximum speed of straight line is 90m/min). The control logic is more complex. In the previous EMS control line, the car will stop when it reaches the station, and it will run to the next station when the beat time is up. But now the car will not stop at each station but stop to the corresponding station according to the task of the goods. Through DEMATIC DIQ system task allocation and 319F PLC logic scheduling control, this line and the previous EMS line has taken a big step from automatic transportation to intelligent transportation.

The system will be powered on and debugged on September 5, 2018. By October 30, the system can automatically judge the destination according to the DIQ system and send the tray to the destination accurately. In a short time of less than 2 months, the system moved from a single device to the system manual, and then from manual to automatic control, and from PLC to DIQ system linkage.

By overcoming a series of problems such as short system modulation cycle, complex control logic and no standard program for reference in the messages between DIQ system and PLC, the technical team of the intermediate company developed an interface program between DIQ system and PLC with the strong technical support of the technical team of the intermediate Company, and completed the project at the project node specified by Party A.

The successful completion of this project also enables us to accumulate certain project experience in the logistics industry, and we believe that we can provide more high-quality control schemes and system engineering in the future material projects.